Drivers of Change.

Discover the new Evolution® SST-Driver. An innovative silicone liner that improves milking performance, lasts longer, and boosts the dairyman’s bottom line. Pre-loaded in a recyclable, single-use shell, it saves both time and money.

Scroll down to see how it can transform your parlor’s efficiency today!

Key benefits.

- Save time and labor costs: Pre-assembled, ready-to-use liners that eliminate disassembly, shell washing, and reloading

- Enhanced durability: Independently trialed and proven to last up to 8,000 milkings – that’s up to three times more milkings than a traditional liner

- Improved cow comfort: Transitional barrel reduces teat ringing and congestion for greater cow comfort

- Perfect for large herds: Designed for high-capacity dairy operations with reliable, efficient performance

- Optimized milking performance: Faster milking with reduced teat stress, improved let down, and better milk flow

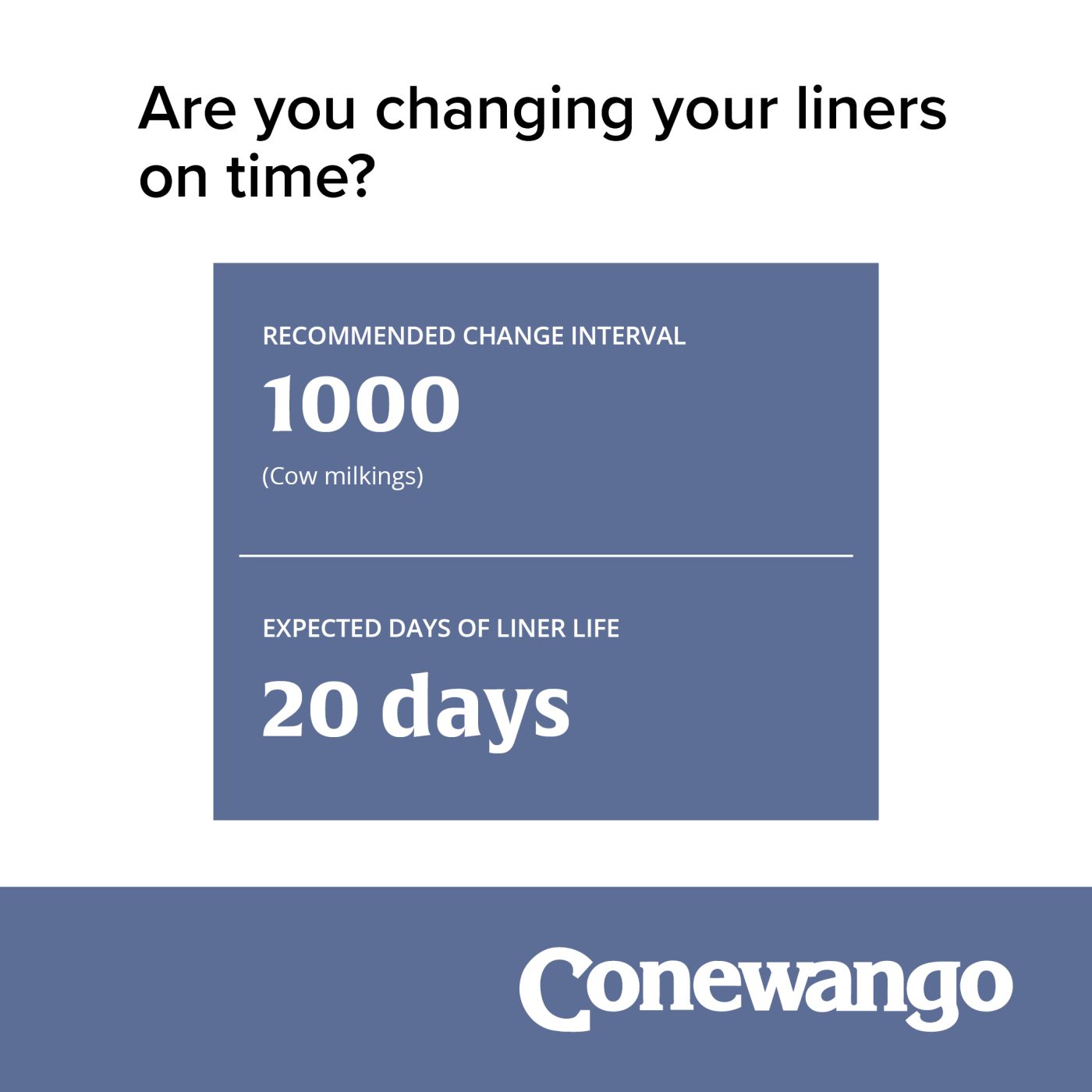

- Cost-effective: Extended-service silicone reduces the need for frequent liner changes, saving time and lowering operating costs

- Independently trialed: Proven on the farm, at real-life working dairies

Innovative design features.

- Silicone for extended service life: Change-out liners less frequently, last up to 8,000 milkings

- Pre-assembled shell: The liner comes pre-loaded in a lightweight, recyclable shell, making installation and liner changes quicker and more efficient

- Patented square hackle: The shell features alignment indicators and a patented square hackle design that creates a strong seal, keeping pulsation lines clean and preventing twisting. Protected under Patent Application 807026

- Locking head design: Eliminates twisting and prevents head of the liner from pulling away from the shell

- Transitional barrel design: Round-to-square barrel minimizes mouthpiece vacuum for greater cow comfort

- Vented and non-vented options: Customizable to suit different milking systems and herd needs

Product specifications & setup information.

Liner dimensions

- 21mm mouthpiece opening

- 10mm lead-in at the end of the claw tube

- 11mm ID at the bumper section tapering to 13.7mm ID at the top of the milk tube for high flow rates

Average claw vacuum peak flow

12.0″ – 12.5″ hg

Best practices for liner transition

Can’t find what you’re looking for?

Speak to one of our representatives for information on any of our products.

Find your local representative